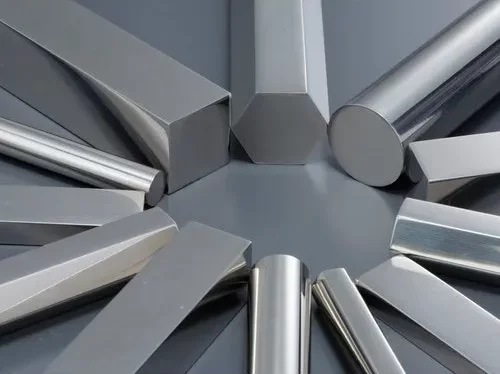

S R tubes are known for coils and cut lengths;Another name for the bar is the Stainless Steel Rod. Applications for bars and rods are contingent upon the grade of the materials and the application’s requirements. Various specifications also define the types of applications and production methods. Hot rolled and cold drawn bars, with the exception of forged bars, must adhere to ASTM A276 stainless steel bar requirements. Round, square, hexagonal, and other extruded shapes are among its possible shapes.

The hot-rolled stainless steel round bar has a higher absolute roughness than the drawn bars. While this roughness is not a problem when the primary concerns are strength and corrosion resistance, the Cold Drawn Stainless Steel Round Bar is the better choice for applications that require a smooth surface, such as exterior fixtures and aesthetic uses. Additionally, these bars can vary in size, typically ranging from a radius of 5 mm to 450 mm. Contact us for pricing and a detailed SS round bar size chart.

We can give Chamfering of 30 or 45 degrees on one or both the ends. For Strain-Hardened Bars, we can supply in B8(304) and B8M(316) in Class1 and Class2.

| Condition | Cold Drawn & Polished | Cold Drawn, Centreless Ground & Polished | Cold Drawn, Centreless Ground & Polished (Strain Hardened) |

| Grades | 201, 202, 303, 304, 304L, 310, 316, 316L, 321, 410, 420, 416, 430, 431, 430F & others | 304, 304L, 316, 316L | |

| Diameter (Size) | 2 mm to 5mm (1/8″ to 3/16″) | 6mm to 22m (1/4″ to 7/8″) | 10mm to 40mm (3/8″ to 1-1/2″) |

| Diameter Tolerance | h9 (Din 671),h11 ASTM A 484 | h9 (Din 671) ASTM A 484 | h9 (Din 671),h11 ASTM A 484 |

| Length | 3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) |

| Length Tolerance | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) | -0/+200mm (-0 ”/+1 feet) |

We can manufacture and offer stainless steel hot rolled round bars and rods in “As rolled condition” or “Heat treated condition”. All products supplied by Metline Industries have passed IGC Practice E test, as well as UT Test.

| Condition | Peeled, Centre less Ground & Polished | Peeled & Polished | Peeled (Rough Turned) | Forged, Rough Turned |

| Grades | 201, 202, 303, 304, 304L, 310, 316, 316L, 321, 410, 420, 416, 430, 431, 430F & others | 304, 304L, 316, 316L, 410, 416, 420, 431 | 303, 304, 304L, 316, 316L, 410, 416, 420, 431 | |

| Diameter (Size) | 20mm to 85mm (3/4 ” to 3–1/4 ”) | 85mm to 140mm (3-1/4 ” to 4–3/4 ”) | 25mm to 140mm (1 ” to 5–1/2 ”) | 150mm to 400mm (6 ” to 16”) |

| Diameter Tolerance | h9 (Din 671) ASTM A 484 | h11 | K12/K13 (Din 1013) | -0mm/+3mm (-0 ”/+0.12 ”) |

| Length | 3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) | 3/4/5.6/6 meter (12/14ft/20feet) | 3 meter -5 meter 10 feet -16 feet |

| Length Tolerance | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) | -0/+200mm or +100mm or +50mm (-0 ”/+1 feet or +4 ” or 2 ”) | -0/+1000mm or 500mm (-0 ”/+3 feet or +2 feet) | -0/+2 meter- -0/+6 feet |

S.R. Tubes is a prominent Indian company specializing in the manufacturing and supply of high-quality stainless-steel pipes and tubes. Established in 2017 as S.R. Tubes in Mumbai, the company has become a trusted name in supporting industrial and architectural projects across the country.

© 2024 SR TUBES Created Y2